An artificial concrete pond is one of the most reliable and durable structures. It can withstand hydrodynamic loads and lasts a very long time. However, the construction of monolithic concrete pools requires a specific sequence of stages. This type of work is performed by specialized companies, offering turnkey construction.

This structure is a hydraulic engineering structure that must withstand static loads. Therefore, the design is handled by specialized companies licensed in this field. Clients are provided with either standard designs that incorporate basic structural solutions or customized designs with structural calculations, which require customized documentation.

The design process itself involves several stages:

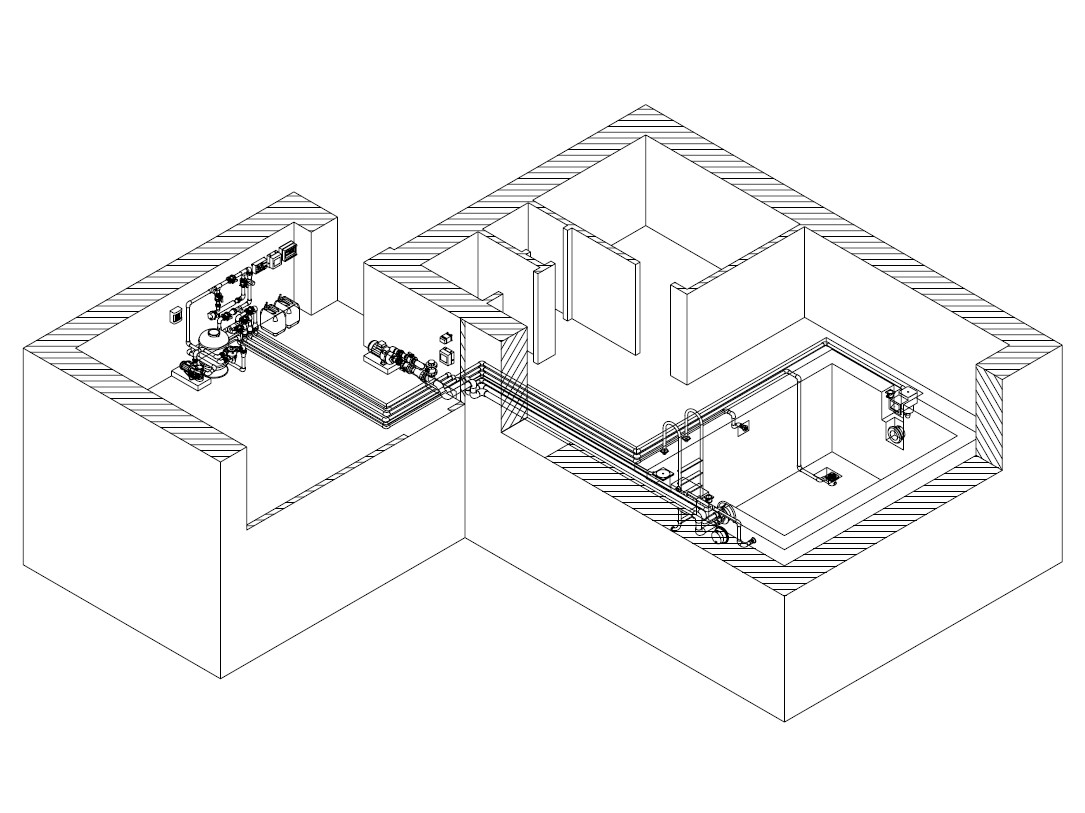

Initially, a working design for the pool is developed, including a set of drawings and consideration of the soil type and groundwater conditions. The design also includes the development of a filtration system, water supply, electrical connections, pumping equipment, and utility installation. An estimate is generated, and the construction cost is determined, taking into account the price per cubic meter of concrete.

All work is carried out in accordance with generally accepted standards.

The construction technology involves constructing formwork into which mortar is poured. The work process also requires a specific sequence:

An area larger than the pool is determined. Having sufficient space allows for optimal installation of utility lines and utilities. Experts recommend choosing a location well-heated by sunlight. It's also important to locate the reinforced concrete pool away from large trees to prevent large amounts of leaves from falling into the water.

Markings are made using ropes and pegs. The pit should be 1 meter larger than the bowl. It should be equipped with additional drainage in the form of a bed of coarse, tightly compacted gravel. Sand should be poured on top to a depth of at least 30 cm.

Ribbed metal rods with a diameter of 10-14 mm are used. They are used to lay out a mesh with 20 x 20 cm cells, binding the material with thin wire. The mesh is installed in two layers, spaced 50 mm above the sand bed and between each other.

Materials used include boards, plywood, or chipboard, preferably coated with varnish, drying oil, or paint beforehand. The formwork is reinforced with spacers installed on each side. The pool is also waterproofed.

The ready-mix concrete is poured after the reinforcement cage has been created. This structure ensures uniform distribution of the mass across the entire surface of the pool. Reinforcement is placed along the perimeter of the walls and bottom. The concrete is poured in a single step to create a monolithic structure and prevent material delamination. Cement grade M400 or higher is recommended for preparing the mortar, ensuring high resistance to mechanical stress and moisture. After the concrete is placed, the surface is covered with a film, ensuring periodic wetting to prevent cracking.

After the formwork is removed, the pool is coated with polymer compounds, which fill even the smallest cracks and imperfections. The choice of material is determined by the type of pool lining to be used.