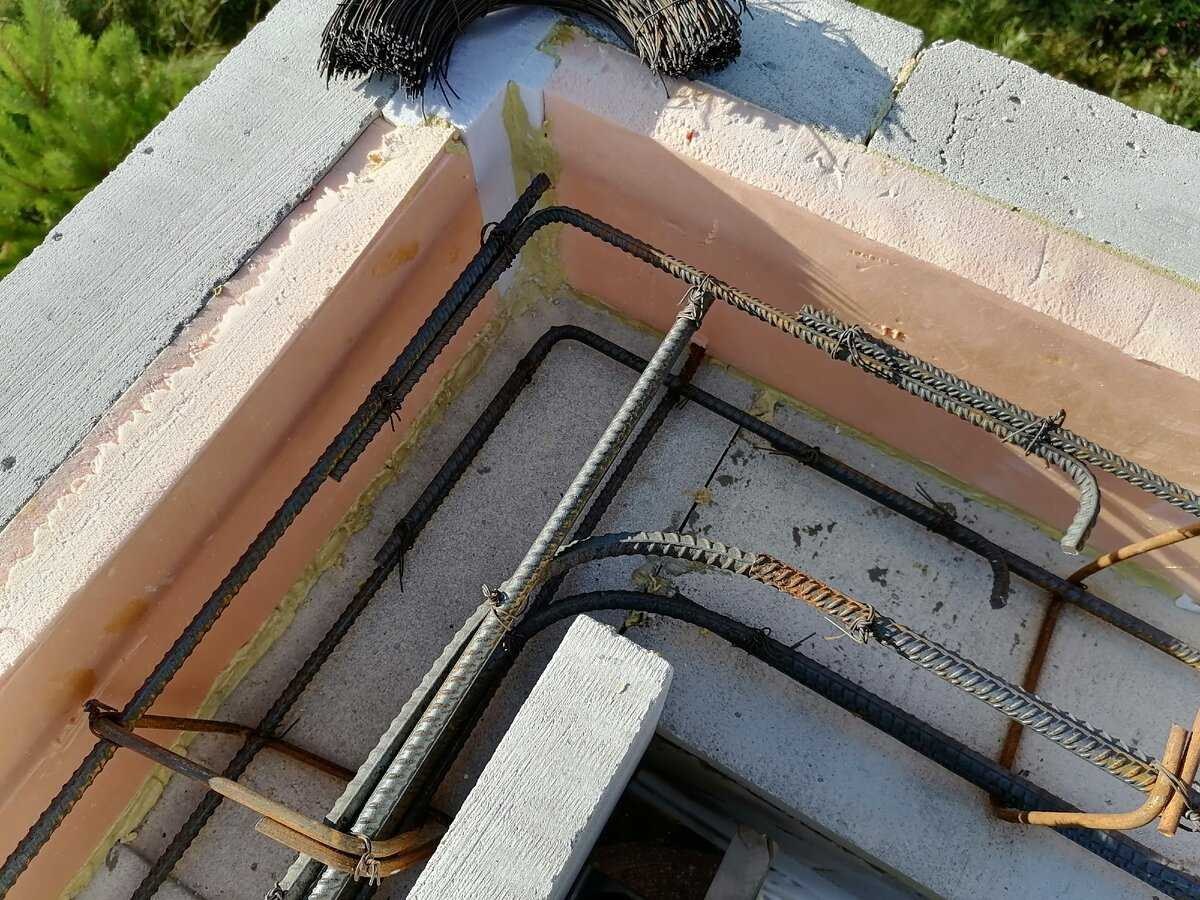

A reinforced concrete belt is an important structural element of a building, ensuring uniform load distribution across the entire area. It also significantly increases the structural strength. A monolithic reinforced concrete belt is manufactured using a combination of reinforced concrete and rebar.

This convenient combination of materials allows the reinforced concrete belt to become the strongest and most durable structural element. This structure is often installed at each floor level or along the building's perimeter.

A foundation and reinforced concrete belt are often combined, and they can also be incorporated into the basement or higher levels of the building. For example, a reinforced concrete belt under the roof can also serve a design function. The thickness and composition of the wall reinforcement can vary widely.

.jpg)

The tools required for concrete pouring the reinforced concrete belt include a concrete mixer, shovel, tape measure, spirit level, rebar cutters, hammer, hammer drill, and screwdriver.

The following materials are required for concrete reinforcement: 10-12 mm diameter rebar, tie wire, M300 concrete, formwork boards, and waterproofing for the structure.

During the preparation phase, the site where the structure will be installed must be cleared of any contaminants, soil reinforcement must be provided if necessary, and the wall must be level with perpendicular corners.

Next, installing the reinforced concrete belt under the floor or on another structure involves the following:

Concrete pouring is included in the list of services offered by construction companies and can be offered as a turnkey project. In this case, experienced specialists completely relieve you of the need to handle the process yourself, providing a ready-to-use structure. The price per cubic meter of concrete is determined at the ordering stage and is finalized after the estimate is prepared. Several factors are taken into account when determining the cost of the work:

Contacting the specialists at RСC ALBA is the best option for those who need qualified assistance and are unable to handle the task independently. Experienced builders will advise on the selection of materials, calculate the key structural parameters, and perform all work in accordance with the required standards.